FROSIO Level III: More Than Just Paperwork – A Deep Dive into Inspection Technology

Imagine an offshore wind turbine relentlessly defying the harsh forces of the sea. Or a sprawling steel bridge safely guiding thousands of vehicles across a river every day. These monuments of engineering have a silent but persistent enemy: corrosion. To protect them, we rely on state-of-the-art coating systems. But the best coating is only as good as its application. This is where the FROSIO-certified inspector comes in. Today, we take a look behind the scenes and do a deep dive into the technical arsenal of inspection methods that a Level III expert masters in their daily work.

The Foundation: Inspection During the Coating Process

The main task of a FROSIO inspector is quality assurance during the application process. It is far more cost-effective to prevent defects than to repair them later under difficult conditions. The inspector is therefore on-site at every critical step, ensuring that the work is carried out exactly according to specification. Their toolkit is fully equipped for the job.

Key tasks include:

- Surface Preparation Check: Does the cleanliness grade (e.g., SA 2.5) and the roughness profile meet the requirements? Comparison samples and surface profile gauges are used here.

- Climate Control: Monitoring temperature, humidity, and dew point is crucial. A coating applied under the wrong climatic conditions can fail later. Digital gauges are constant companions for this.

- Wet and Dry Film Thickness Measurement: Using wet film combs and digital coating thickness gauges (based on magnetic induction or eddy current), it is ensured that exactly the prescribed amount of protective material is applied to the surface.

- Cross-Cut and Adhesion Testing: After curing, the adhesion of the coating to the substrate is checked. Only a perfectly adhering coating offers lasting protection.

A Look Beneath the Surface: Non-Destructive Testing (NDT)

Often, defects are not in the coating itself, but in the underlying steel, for example, in welds. A FROSIO inspector must therefore also be familiar with the methods of non-destructive testing (NDT), known internationally as ZfP (Zerstörungsfreie Prüfung) in German, to be able to comprehensively assess the condition of a structure.

Surface Inspection Methods

These methods are excellent for finding defects on or just below the surface.

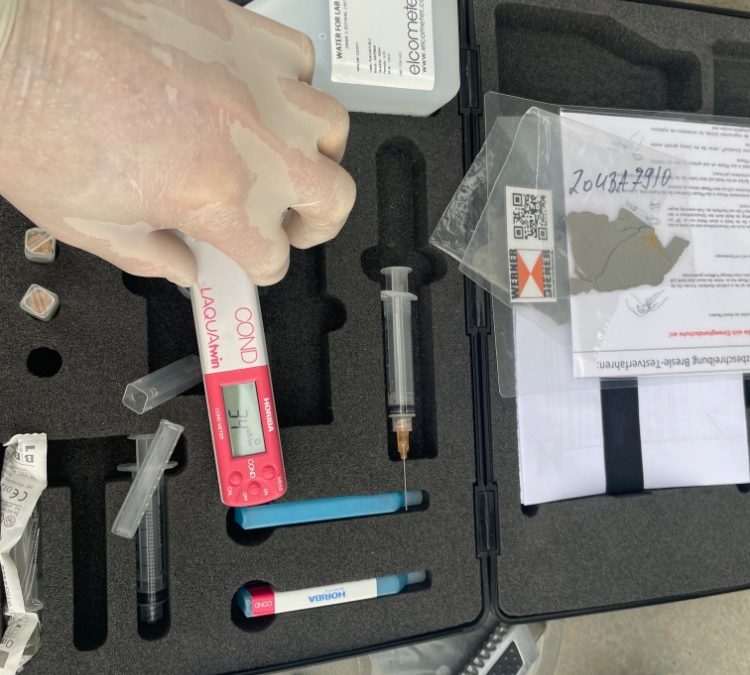

A crucial step in quality assurance: Using a digital coating thickness gauge, the certified inspector determines the Dry Film Thickness (DFT) of the final coating. This measurement ensures that the protective layer meets the exact specifications. A layer that is too thin would compromise corrosion protection, while a layer that is too thick can lead to cracking, adhesion problems, and extended curing times. Only adherence to the specified values guarantees the full protective effect and longevity of the structure.

- VT – Visual Testing: The inspector’s trained eye is the most powerful tool. Cracks, pores, or a faulty weld geometry can often be detected visually.

- MT – Magnetic Particle Testing: Ideal for ferromagnetic materials. A magnetic field is passed through the component. Defects such as fine cracks disturb this field and attract magnetic particles, which make the defect visible.

- PT – Dye Penetrant Testing: In this method, a colored (usually red) or fluorescent liquid is applied to the surface. It penetrates even the finest cracks through capillary action. After cleaning, a developer is applied, which “draws” the liquid out of the crack and clearly indicates the defect.

Volumetric Testing Methods

To detect defects inside a component, more complex methods are necessary.

- UT – Ultrasonic Testing: Similar to a medical ultrasound, high-frequency sound waves are sent into the material. Defects inside (e.g., voids or bonding defects) reflect the sound, and the echo is captured and visualized by the testing device. Modern variants like PAUT (Phased Array) and TOFD (Time of Flight Diffraction) allow for an even more precise, pictorial representation of the component’s interior.

- RT – Digital Radiographic Testing: Similar to a doctor’s x-ray, the component is irradiated. Material defects or differences in thickness weaken the radiation to varying degrees, which becomes visible as an image on a digital detector.

You can find a good video that clearly explains magnetic particle testing here:

The Material Check: Positive Material Identification (PMI)

Was the specified steel alloy actually used during manufacturing or repair? A mix-up can have catastrophic consequences. Positive Material Identification (PMI) provides quick, non-destructive certainty in this regard.

- X-ray Fluorescence (XRF): A handheld “gun” device scans the metal and identifies its key alloying elements in seconds. It is the most widely used method for mobile applications. A limitation is that it cannot detect very light elements like carbon.

- Optical Emission Spectrometry (OES): This method can also precisely determine carbon and other light elements. Although the devices are larger, they are portable and used for precise on-site analyses where carbon concentration is critical.

The Hardness Test: Portable Hardness Testing (HT)

The hardness of a material provides important information about its condition, especially after welding or heat treatments. A weld seam or the heat-affected zone (HAZ) can have different hardness levels than the base material, which can lead to stress and potential weak points. With portable hardness testers, the inspector can non-destructively determine the hardness value directly on-site and ensure that it complies with standards (e.g., NACE MR0175).

The Inspector as an Alpinist: Rope Access Technology

What good are the best inspection tools if the location to be inspected—such as the tip of a wind turbine blade or the suspension cable of a bridge—seems unreachable? Many FROSIO inspectors are therefore additionally trained as industrial rope access technicians (often certified to IRATA or FISAT standards). This combination of technical expertise and alpinistic skills allows them to literally reach every point of a structure to ensure seamless quality assurance.

Conclusion

The work of a FROSIO Level III Inspector is a fascinating mix of in-depth material and process understanding, the masterful use of high-tech inspection equipment, and often physical exertion under demanding conditions. They are the crucial guarantor for ensuring that our valuable steel structures are safe and achieve their maximum service life.

Further Links:

Frosio

The official Norwegian certification body for surface treatment inspectors.

DGZfP

The German Society for Non-Destructive Testing e.V.

AMPP

AMPP (Association for Materials Protection and Performance), which was formed by the merger of NACE and SSPC.