Frosio is a renowned leader in the field of corrosion prevention and corrosion protection. With extensive expertise, they provide critical solutions to industries affected by corrosion.

Their work is crucial in maintaining the integrity and longevity of infrastructure and equipment across various sectors. By applying their knowledge and innovative techniques, Frosio helps businesses mitigate the risks associated with corrosion, ensuring operational safety and efficiency.

Key Takeaways

- Expertise in corrosion prevention and protection

- Critical solutions for industries affected by corrosion

- Innovative techniques for mitigating corrosion risks

- Enhancing operational safety and efficiency

- Maintaining infrastructure and equipment integrity

The Frosio Legacy: Over 30 Years of Corrosion Expertise

With over three decades of experience, Frosio has established itself as a leader in corrosion prevention and protection. This legacy is built on a foundation of corrosion expertise and a relentless pursuit of innovation.

Company History and Evolution

Frosio’s journey began with a simple yet ambitious goal: to provide top-notch corrosion protection services. Over the years, the company has evolved significantly, expanding its services and geographical reach. Today, Frosio is recognized globally for its comprehensive solutions in corrosion prevention.

Core Values and Mission

At the heart of Frosio’s success are its core values: a commitment to excellence, customer satisfaction, and continuous improvement. Frosio’s mission is to safeguard assets from the detrimental effects of corrosion, ensuring the longevity and integrity of its clients’ infrastructure. By living these values, Frosio has built a reputation for reliability and expertise in the industry.

Frosio’s legacy is not just about its history; it’s about the trust it has earned from its clients and its ongoing commitment to combating corrosion. As the company continues to grow and innovate, its core mission remains unchanged: to protect and preserve the world’s infrastructure through its unparalleled corrosion expertise.

Understanding Corrosion: Causes and Consequences

Corrosion, a natural process, has significant implications for infrastructure and industry. It involves the deterioration of materials, typically metals, due to chemical or electrochemical reactions with their environment. Understanding the causes and consequences of corrosion is essential for developing effective prevention and mitigation strategies.

The Science Behind Corrosion Processes

The science behind corrosion is rooted in electrochemistry. When a metal is exposed to an electrolyte, such as moisture or saltwater, it can undergo oxidation, leading to the formation of ions. This process can be accelerated by various factors, including the presence of oxygen, temperature fluctuations, and the metal’s composition. Corrosion science seeks to understand these mechanisms to predict and prevent corrosion.

Economic Impact of Corrosion Damage

The economic impact of corrosion is substantial. It is estimated that corrosion costs the global economy billions of dollars annually. These costs arise from the need for repairs, replacements, and maintenance of corroded infrastructure, equipment, and vehicles. Corrosion consequences can also include downtime, loss of productivity, and environmental damage.

| Industry | Annual Cost of Corrosion |

|---|---|

| Infrastructure | $22.6 billion |

| Utilities | $5.4 billion |

| Transportation | $2.9 billion |

Early Warning Signs of Corrosion Issues

Identifying early warning signs of corrosion is crucial for preventing its detrimental effects. Some common indicators include visible signs of rust or corrosion, leaks, or changes in equipment performance. Regular inspections and monitoring can help detect corrosion early, allowing for timely intervention.

- Visible rust or corrosion

- Leaks or water damage

- Changes in equipment performance

Frosio Corrosion Protection: Comprehensive Solutions

Frosio offers a comprehensive suite of corrosion protection solutions tailored to meet the diverse needs of various industries. With a deep understanding of the complexities of corrosion, Frosio has developed a multifaceted approach that encompasses preventative measures, remediation services, and customized protection plans.

Preventative Strategies and Methodologies

Frosio’s preventative strategies are designed to mitigate the risk of corrosion from the outset. This includes the application of advanced coating systems, cathodic protection, and rigorous inspection and monitoring protocols. By identifying potential corrosion issues early, Frosio’s experts can implement effective preventative measures to safeguard assets.

Key preventative methodologies include:

- Advanced coating systems to protect surfaces

- Cathodic protection to reduce corrosion risk

- Regular inspections and monitoring to detect early signs of corrosion

Remediation and Restoration Services

When corrosion has already occurred, Frosio’s remediation and restoration services are crucial in restoring damaged assets to their original condition. This involves assessing the extent of the damage, developing a tailored remediation plan, and executing the necessary repairs or replacements.

Frosio’s remediation services include:

- Assessment and diagnosis of corrosion damage

- Development of customized remediation plans

- Execution of repairs and replacements as needed

Customized Protection Plans

Frosio understands that every client has unique needs and challenges. Therefore, the company develops customized protection plans that are tailored to the specific requirements of each project. These plans are designed to provide long-term corrosion protection, minimizing the risk of future damage.

By combining preventative strategies, remediation services, and customized protection plans, Frosio offers a comprehensive approach to corrosion protection that is both effective and sustainable.

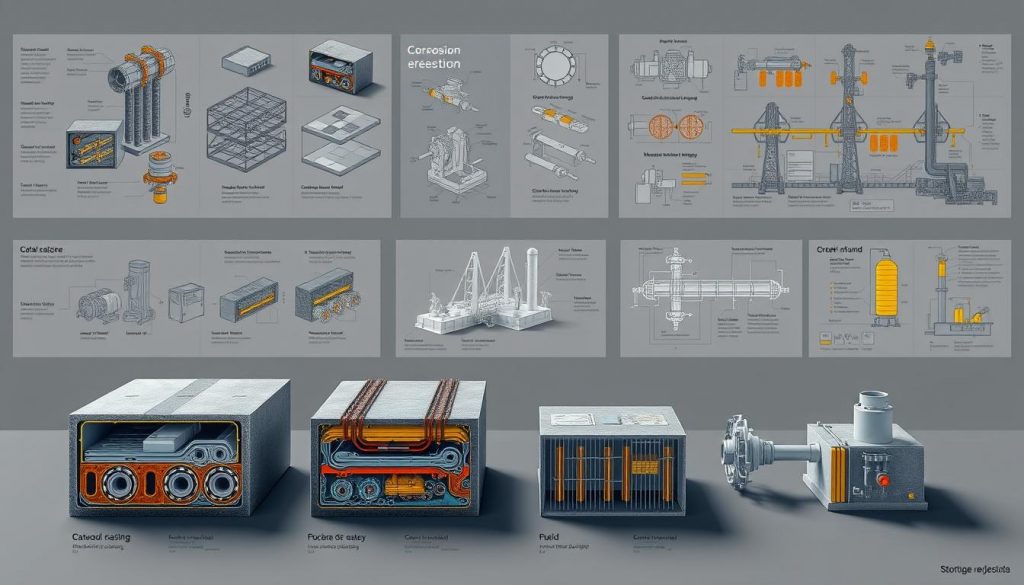

Advanced Technologies in Corrosion Prevention

Advanced technologies are revolutionizing the field of corrosion prevention, and Frosio is leading the charge. By integrating the latest innovations in coating systems, cathodic protection, and monitoring technologies, Frosio provides comprehensive solutions to combat corrosion effectively.

Cutting-Edge Coating Systems

Frosio employs state-of-the-art coating systems that offer enhanced durability and protection against corrosive elements. These advanced coatings are designed to withstand harsh environments, reducing the need for frequent maintenance and thereby lowering overall costs. Key benefits include:

- Increased longevity of structures

- Improved resistance to chemical and environmental degradation

- Reduced maintenance costs over time

Cathodic Protection Innovations

Cathodic protection is a critical method for preventing corrosion, especially in metal structures. Frosio has pioneered innovations in cathodic protection systems, ensuring that they are more efficient and effective. These advancements include:

| Innovation | Description | Benefit |

|---|---|---|

| Advanced Anode Materials | New materials that enhance the efficiency of cathodic protection systems | Longer lifespan and reduced maintenance |

| Smart Rectifiers | Rectifiers that adjust output based on environmental conditions | Optimized protection and energy savings |

Monitoring and Inspection Technologies

Effective corrosion prevention also involves continuous monitoring and inspection. Frosio utilizes advanced monitoring and inspection technologies to detect early signs of corrosion, allowing for timely intervention. These technologies include:

- Ultrasonic thickness testing

- Corrosion under insulation (CUI) detection

- Advanced data analytics for predictive maintenance

Industries Served by Frosio

Frosio’s extensive experience in corrosion protection has enabled the company to serve a wide array of industries effectively. With a broad range of services, Frosio caters to various sectors, providing comprehensive solutions to mitigate corrosion.

Marine and Offshore Applications

Frosio’s services are crucial in marine and offshore environments where corrosion is a significant concern. The company provides advanced coating systems and cathodic protection solutions to protect vessels, platforms, and other marine infrastructure. By ensuring the integrity of these assets, Frosio helps prevent costly repairs and downtime.

Some of the specific services offered include:

- Coating inspections and maintenance

- Cathodic protection design and installation

- Corrosion monitoring and inspection

Industrial Facilities and Manufacturing

In industrial facilities and manufacturing plants, corrosion can lead to equipment failure and production halts. Frosio addresses these challenges by offering customized corrosion protection plans, including coating solutions, cathodic protection, and monitoring technologies. This proactive approach helps maintain operational efficiency and extends the lifespan of equipment.

| Industry | Corrosion Protection Solutions | Benefits |

|---|---|---|

| Marine and Offshore | Coating systems, cathodic protection | Reduced maintenance, extended asset life |

| Industrial Facilities | Customized coating plans, monitoring technologies | Operational efficiency, cost savings |

| Infrastructure and Civil Engineering | Cathodic protection, coating solutions | Enhanced durability, reduced repair costs |

| Oil and Gas | Advanced coating systems, cathodic protection | Increased safety, minimized downtime |

Infrastructure and Civil Engineering

Frosio’s corrosion protection services are also vital in infrastructure and civil engineering projects, such as bridges, buildings, and pipelines. By applying advanced coating systems and cathodic protection, Frosio helps ensure the structural integrity of these critical assets, reducing the need for costly repairs and enhancing public safety.

Oil and Gas Sector Solutions

In the oil and gas sector, Frosio provides specialized corrosion protection solutions to safeguard equipment and infrastructure. This includes advanced coating systems for pipelines and storage tanks, as well as cathodic protection for offshore platforms and onshore facilities. By mitigating corrosion risks, Frosio contributes to the safe and efficient operation of oil and gas operations.

The Frosio Certification System and Standards

With a strong emphasis on quality, Frosio’s certification system adheres to rigorous international standards, ensuring that clients receive the highest level of service in corrosion prevention and protection.

Frosio’s commitment to excellence is reflected in its comprehensive certification framework, which is designed to meet the evolving needs of industries affected by corrosion.

International Certification Framework

The Frosio certification framework is built on a foundation of international standards, providing a robust structure for the qualification of professionals in the field of corrosion protection.

This framework ensures that Frosio-certified inspectors and professionals have the necessary knowledge and skills to deliver high-quality services that meet global best practices.

| Standard | Description | Application |

|---|---|---|

| ISO 12944 | Paints and varnishes for corrosion protection | Coating specifications for various environments |

| ISO 8501 | Preparation of steel substrates before coating | Surface preparation standards for coating application |

| NACE MR0175/ISO 15156 | Materials for use in H2S-containing environments | Material selection for sour service applications |

Training and Inspector Qualification Process

Frosio’s training and inspector qualification process is rigorous and comprehensive, involving both theoretical and practical training modules.

Inspectors undergo extensive training, covering topics such as coating application, cathodic protection, and inspection techniques, to ensure they are fully equipped to assess and manage corrosion protection projects.

“The Frosio certification is a mark of excellence in the corrosion protection industry, signifying a professional’s ability to deliver high-quality services that meet international standards.”

Benefits of Working with Certified Professionals

Engaging with Frosio-certified professionals offers numerous benefits, including assurance of quality workmanship, compliance with international standards, and enhanced project efficiency.

Clients can trust that Frosio-certified inspectors have the expertise and knowledge required to effectively manage corrosion protection projects, minimizing risks and ensuring long-term asset integrity.

The Frosio Consultation Process

Understanding the unique needs of each client is at the heart of Frosio’s consultation process. This process is designed to provide comprehensive corrosion protection solutions tailored to the specific requirements of various industries.

Initial Assessment and Evaluation

The first step in the Frosio consultation process involves a thorough initial assessment and evaluation of the client’s assets and facilities. This stage is crucial in identifying potential corrosion risks and understanding the current state of the infrastructure. Frosio’s experts use advanced technologies and methodologies to assess the condition of the assets, providing a detailed report that outlines the findings and recommendations for future actions.

Solution Development and Implementation

Following the initial assessment, Frosio’s team develops a customized solution that addresses the identified corrosion concerns. This involves selecting the most appropriate corrosion protection strategies and methodologies, which are then implemented by Frosio’s skilled professionals. The solution implementation phase is carried out with minimal disruption to the client’s operations, ensuring that their business continuity is maintained.

Ongoing Maintenance and Support

After the implementation of the corrosion protection solutions, Frosio provides ongoing maintenance and support to ensure the long-term integrity of the client’s assets. This includes regular inspections, monitoring, and maintenance activities, all designed to prevent future corrosion issues. By providing continuous support, Frosio helps clients avoid costly repairs and downtime, safeguarding their investments.

Frosio’s consultation process is a comprehensive and client-focused approach to corrosion protection, ensuring that clients receive the best possible solutions for their specific needs.

Case Studies: Successful Corrosion Prevention Projects

Through their comprehensive approach to corrosion prevention, Frosio has achieved significant success in diverse industrial settings. This success is best illustrated through various case studies that highlight the challenges overcome and the achievements made across different environments and industries.

Marine Environment Challenges Overcome

Frosio has successfully tackled corrosion challenges in marine environments, where the combination of saltwater and humidity accelerates degradation. Advanced coating systems and cathodic protection have been effectively used to protect offshore platforms and ships, extending their operational lifespan.

One notable case study involved the application of a specialized coating to a marine vessel, significantly reducing maintenance costs and downtime. This project demonstrated Frosio’s ability to deliver tailored solutions that meet the unique demands of marine environments.

Industrial Facility Protection Success Stories

In industrial facilities, corrosion can lead to equipment failure and costly downtime. Frosio has implemented effective corrosion prevention strategies, including protective coatings and corrosion monitoring systems, to safeguard critical infrastructure.

A success story from Frosio’s portfolio involved the protection of a chemical processing plant, where the implementation of a comprehensive corrosion management plan resulted in a significant reduction in maintenance costs and improved operational efficiency.

Infrastructure Preservation Achievements

Frosio has also made significant contributions to infrastructure preservation through innovative corrosion prevention techniques. By applying advanced materials and preservation methods, Frosio has helped extend the lifespan of critical infrastructure such as bridges and roads.

One achievement worth noting is the preservation of a major bridge, where Frosio’s team applied a cutting-edge coating system to protect the structure from corrosion, ensuring its stability and safety for years to come.

These case studies demonstrate Frosio’s expertise and commitment to delivering effective corrosion prevention solutions across various industries and environments.

Conclusion: Securing Your Assets with Industry-Leading Corrosion Protection

Effective corrosion protection is crucial for safeguarding assets across various industries, from marine and offshore applications to industrial facilities and infrastructure projects. Frosio’s expertise and comprehensive solutions play a vital role in preventing corrosion damage, thereby ensuring the longevity and integrity of critical assets.

With over 30 years of experience and a commitment to industry-leading practices, Frosio provides asset security through innovative corrosion protection solutions. Their certified professionals work closely with clients to develop customized protection plans, leveraging advanced technologies and methodologies to mitigate corrosion risks.

By choosing Frosio, industries can benefit from enhanced asset security, reduced maintenance costs, and improved operational efficiency. Frosio’s dedication to delivering exceptional corrosion protection services solidifies their position as a trusted partner for industries seeking to protect their valuable assets.