Introduction to Industrielle Messtechnik

Discovering the essence of industrielle Messtechnik (industrial measuring technology) can feel like navigating through a complex labyrinth of precision, quality, and innovation. It intertwines with my professional journey, where each project serves as a testimony to the transformative impact of meticulous surface treatment and the relentless pursuit of excellence in corrosion protection. Industrial measuring technology not only underpins the foundation of modern manufacturing but also embodies the pivotal role of ensuring enduring quality and reliability across diverse industries.

Significance of Accurate Measurements

Accuracy is the linchpin in industrielle Messtechnik. It’s fascinating how a precise measurement can be the difference between success and failure in creating products that not only meet but exceed expectations. Reflecting on countless projects, the precision in thickness readings using Digital Dry Film Thickness (DFT) measurements has been critical. Such accuracy ensures the applied coatings achieve their protective purpose, safeguarding structures from the relentless onslaught of corrosion.

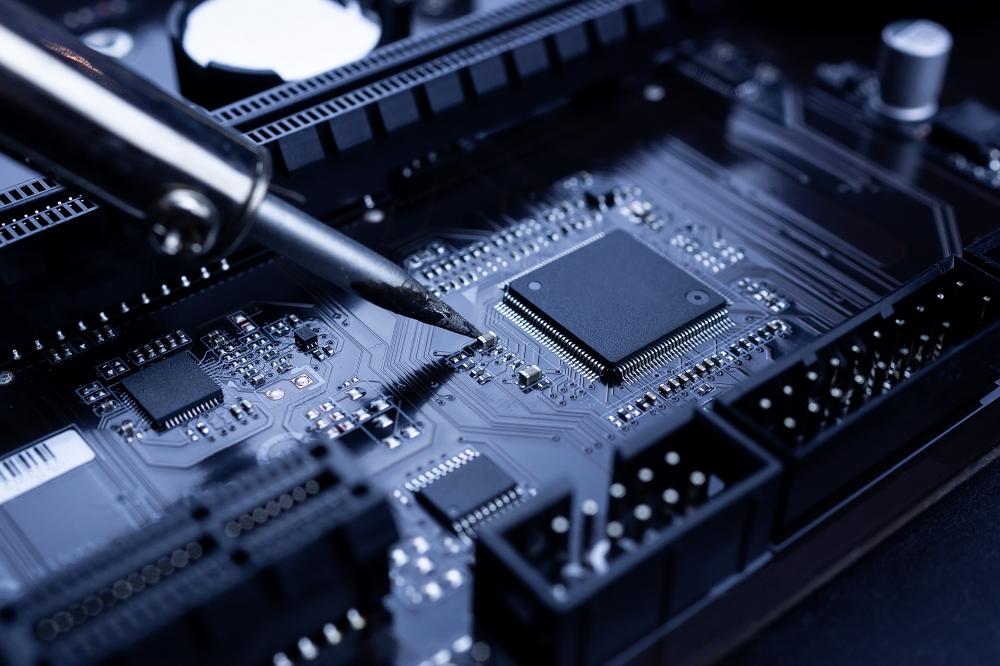

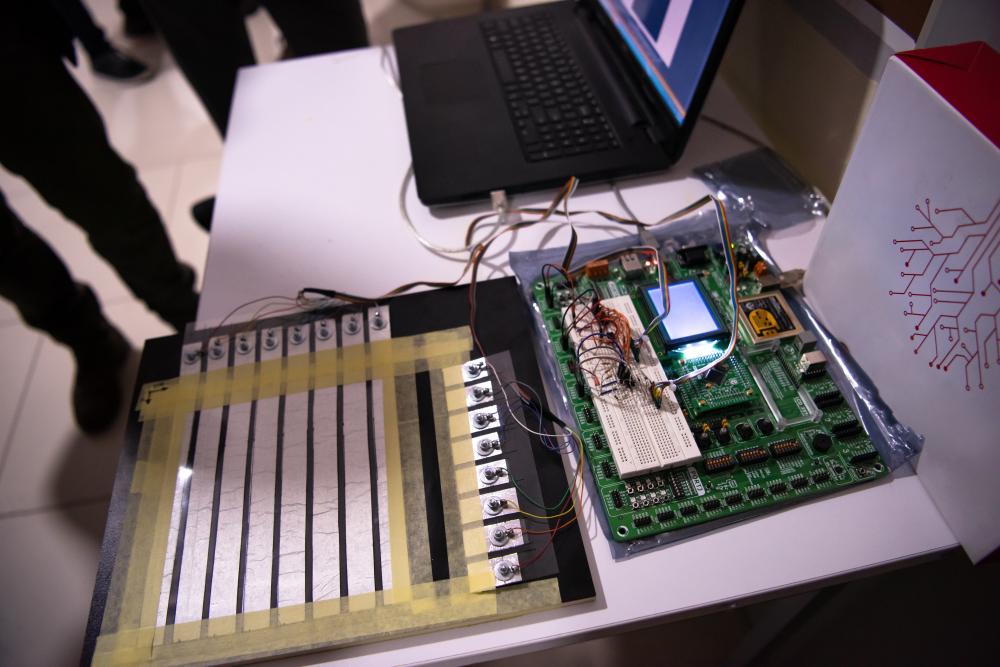

Exploring Technologies in Messtechnik

Industrielle Messtechnik thrives on technological advancement. From the foundations of traditional methods to the forefront of innovation, technologies such as 3D laser scanning and digital microscopy have revolutionized the way we understand and analyze materials. In my journey, integrating such advanced technologies has empowered our team to deliver solutions that embody precision and stand the test of time.

The Human Factor

The essence of industrielle Messtechnik, while deeply rooted in technology, is magnified by human insight and expertise. I’ve witnessed how the nuanced understanding and experience of a skilled practitioner, like our FROSIO inspector Sven Svoboda, can elevate the outcome of any project. It’s a vivid reminder that behind every successful application of industrielle Messtechnik lies a team of dedicated professionals whose expertise breathes life into technology.

Corrosion Protection and Messtechnik

Corrosion protection stands as a testament to the power of industrielle Messtechnik. The meticulous application of coatings, assessed and verified through precise measurements, exemplifies how industrielle Messtechnik not only enhances product longevity but also conserves resources and protects environments. Techniques like sandblasting and spray galvanizing, pivotal in preparing surfaces, are quintessential examples of how industrielle Messtechnik intertwines with corrosion protection, ensuring efficacy and durability.

Quality Assurance Methods

Quality assurance in industrielle Messtechnik transcends mere compliance–it embodies a commitment to excellence. Methods such as the Bresle salt test, which quantifies salt contamination levels, and peel adhesion strength assessments, are indispensable in our toolkit. These methods not only assure quality but also predict longevity, enabling us to set benchmarks that define industry standards.

Embracing Challenges

The realm of industrielle Messtechnik is not without its challenges, yet it is precisely these obstacles that fuel innovation and progress. Addressing complex issues, whether through developing new measurement techniques or adapting existing ones to novel applications, has been both a challenge and a reward. Each solved problem represents a step forward, not just for our team but for the field as a whole.

Future Perspectives

Looking to the future, industrielle Messtechnik holds the promise of even greater advancements. Anticipating changes, particularly in the realm of digital transformation and artificial intelligence, inspires us to continually adapt and innovate. The prospect of increasingly integrated systems and automated processes opens new horizons for precision, efficiency, and creativity in industrial measurement.

Conclusion

Industrielle Messtechnik, with its blend of precision, innovation, and human expertise, continues to be a cornerstone of quality and reliability in modern manufacturing. As we navigate through the evolving landscape of industrial measurement, the lessons learned and the challenges overcome serve as beacons that guide our journey towards excellence. In every layer of coating, in every micron measured, resides the essence of our dedication and the measure of our success.

-

Understanding the core principles of industrielle Messtechnik.

-

Exploring the impact of technological advancements on measurement accuracy.

-

Highlighting the critical role of human expertise in leveraging technology for better outcomes.

-

Assessing the symbiotic relationship between corrosion protection and industrielle Messtechnik.

-

Emphasizing the importance of quality assurance methods for setting industry standards.

Who owns the Zeiss group?

In the realm of optical and optoelectronic technology, the Carl Zeiss AG, often simply referred to as ZEISS, stands out significantly. It is owned by the Carl-Zeiss-Stiftung, or the Carl Zeiss Foundation. This unique ownership structure plays a pivotal role in ensuring that the company not only focuses on profit but also invests heavily in research and development, which in turn fuels innovation. This approach has enabled ZEISS to maintain its position at the forefront of technological advancements in optics and beyond.

What is the legal name of the Zeiss group?

The legal name of the renowned optics and optoelectronic giant is Carl Zeiss AG. This iconic name is deeply entrenched in the history of optical science and technology. It’s fascinating to think about how the company, founded back in 1846, has evolved over the years, from a small workshop to a global leader in the fields of optics and optoelectronics, all the while retaining its original name which continues to stand as a beacon of quality and innovation in the industry.

What are the divisions of ZEISS?

ZEISS operates through several key divisions, each dedicated to pushing the boundaries in their respective fields. These divisions include Semiconductor Manufacturing Technology, Medical Technology, Research Microscopy Solutions, Vision Care/Consumer Products, and Industrial Quality & Research. It’s this diversification that allows ZEISS to apply its optical expertise across a wide array of applications, from enabling advanced manufacturing processes to improving healthcare outcomes and beyond. The synergy between these divisions fuels a cycle of innovation that benefits not just ZEISS but the broader technology and science communities.

Who makes ZEISS lenses?

ZEISS lenses are produced by Carl Zeiss AG itself, utilizing its vast network of manufacturing facilities spread across the globe. The company prides itself on the rigorous standards of quality and precision that go into the making of each lens, whether it’s for eyeglasses, camera optics, binoculars, or medical equipment. It’s the combination of experienced craftsmanship and cutting-edge technology that ensures each ZEISS lens offers unparalleled clarity and performance, embodying over a century of optical innovation.

Why is accuracy so critical in industrial measuring technology?

Accuracy in industrial measuring technology, or industrielle Messtechnik, is absolutely critical because it directly impacts the quality, safety, and efficiency of products and processes across various industries. Imagine implementing a coating that’s meant to protect a bridge from corrosion but failing to apply it with precise thickness due to inaccurate measurements. The results could range from premature wear and tear to catastrophic failure, risking lives and resources. Therefore, maintaining high accuracy in measurements ensures the reliability and longevity of structures and products, reflecting our dedication to safeguarding and enhancing quality at every turn.

How does human expertise enhance the effectiveness of industrielle Messtechnik?

While advanced technologies undoubtedly play a critical role in industrielle Messtechnik, the nuanced understanding and expertise of seasoned professionals enhance its effectiveness exponentially. For instance, our own FROSIO inspector, Sven Svoboda, brings a level of insight and experience that cannot be replicated by machines alone. His ability to interpret data, anticipate potential issues, and apply innovative solutions breathes life into the technology, ensuring outcomes that stand the test of time. It’s a powerful reminder that at the heart of every technological advancement lies human ingenuity and dedication.

In what ways does industrielle Messtechnik contribute to corrosion protection?

Industrielle Messtechnik plays a pivotal role in corrosion protection by ensuring that coating applications meet precise specifications for thickness, adherence, and environmental resistance. Techniques like sandblasting and spray galvanizing, crucial for preparing surfaces, rely heavily on accurate measurements to achieve the desired outcome. By meticulously assessing and verifying the application process, industrielle Messtechnik helps in enhancing the durability and efficacy of corrosion protection measures, thus extending the lifespan of assets and structures. This meticulous approach to quality assurance exemplifies our commitment to preserving not just the materials we work with but also the environments they inhabit.

Resources

- NACE International – NACE International is a nonprofit organization focused on the corrosion control industry, providing resources, training, and certification programs.

- ASTM International – ASTM International is a globally recognized leader in the development and delivery of international voluntary consensus standards related to materials, products, systems, and services.

- International Organization for Standardization (ISO) – ISO is an independent, non-governmental international organization that develops and publishes international standards to ensure the quality, safety, and efficiency of products, services, and systems.

- ASM International – ASM International is the world’s largest association of materials engineers and scientists, providing resources, education, and networking opportunities in the field of materials science and engineering.

- Nondestructive Testing Resource Center – NDT.org is a comprehensive portal for resources, news, and information related to nondestructive testing (NDT) methods and technologies.